Performance Analysis of Diesel Generators

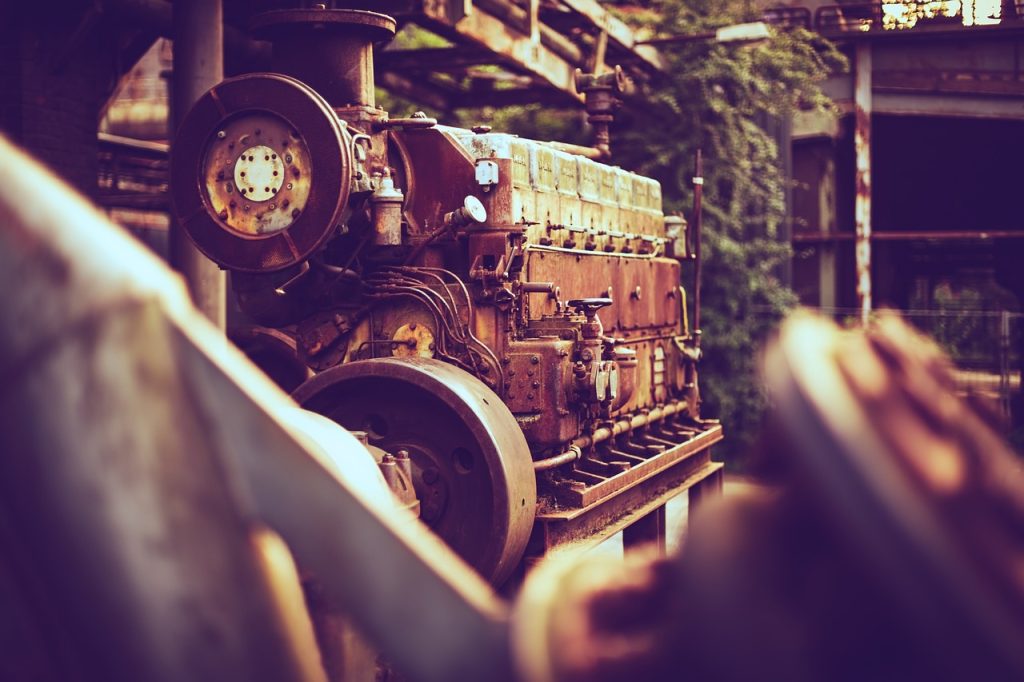

Introduction Diesel generators are commonly used in various industries, commercial buildings, and residential settings as a reliable source of backup power. These generators are known for their robustness, durability, and efficiency in providing continuous power supply during electrical outages. In order to ensure optimal performance and reliability, it is essential to conduct regular performance analysis of diesel generators. This article aims to explore the key aspects of performance analysis for diesel generators, including the importance of monitoring, key performance parameters, testing methods, and maintenance practices. Importance of Performance Analysis Performance analysis of diesel generators is crucial for ensuring the reliability and efficiency of the power generation system. By monitoring and analyzing the performance of the generator, operators can identify any potential issues or inefficiencies before they escalate into major problems. Regular performance analysis helps in detecting abnormalities, such as voltage fluctuations, frequency variations, fuel consumption discrepancies, and overheating, which can impact the overall performance of the generator. By addressing these issues promptly, operators can prevent unexpected downtime, reduce maintenance costs, and extend the lifespan of the generator. Key Performance Parameters Several key performance parameters are essential for evaluating the performance of diesel generators. These parameters provide valuable insights into the operational efficiency, reliability, and overall health of the generator. Some of the key performance parameters include: 1. Voltage Output: Voltage output is a critical parameter that indicates the electrical power supplied by the generator. Monitoring the voltage output helps in ensuring that the generator is providing the required voltage levels to the connected load. 2. Frequency Output: Frequency output refers to the frequency of the alternating current (AC) output produced by the generator. Maintaining the correct frequency output is essential for ensuring the compatibility of the generator with the electrical equipment connected to it. 3. Fuel Consumption: Monitoring fuel consumption is crucial for assessing the efficiency of the generator. High fuel consumption can indicate inefficiencies in the engine or fuel system, leading to increased operating costs. 4. Temperature Levels: Monitoring the temperature levels of the engine, alternator, and other critical components is vital for preventing overheating and ensuring optimal performance. High temperatures can lead to component failure and reduced efficiency. 5. Load Capacity: Load capacity refers to the maximum amount of electrical load that the generator can handle. Monitoring the load capacity helps in preventing overloading, which can damage the generator and connected equipment.  Testing Methods Various testing methods can be used to analyze the performance of diesel generators effectively. These testing methods help in assessing the key performance parameters and identifying any deviations from the expected values. Some of the commonly used testing methods for diesel generators include: 1. Load Bank Testing: Load bank testing involves simulating real-world operating conditions by applying a load to the generator. This test helps in evaluating the performance of the generator under different load levels and assessing its capacity to handle varying loads. 2. Voltage and Frequency Testing: Voltage and frequency testing involves measuring the voltage and frequency output of the generator using specialized equipment. This test helps in ensuring that the generator is providing the correct voltage and frequency levels. 3. Fuel Consumption Analysis: Fuel consumption analysis involves monitoring the fuel consumption of the generator over a specific period. By analyzing fuel consumption patterns, operators can identify any anomalies and optimize fuel usage. 4. Thermal Imaging: Thermal imaging is used to detect temperature variations in the engine, alternator, and other components of the generator. This non-invasive method helps in identifying overheating issues and potential failures. Maintenance Practices In addition to performance analysis, regular maintenance practices are essential for ensuring the optimal performance and longevity of diesel generators. Proper maintenance helps in preventing breakdowns, reducing downtime, and extending the lifespan of the generator. 300KW Diesel Generator For Sale of the key maintenance practices for diesel generators include: 1. Regular Inspections: Conducting regular visual inspections of the generator for signs of wear, leaks, or damage is essential for detecting potential issues early on. 2. Oil and Filter Changes: Regular oil and filter changes are necessary to ensure the proper lubrication and cooling of the engine. Dirty oil and filters can lead to engine damage and reduced efficiency. 3. Cooling System Maintenance: The cooling system of the generator should be inspected and maintained regularly to prevent overheating. This includes checking coolant levels, inspecting hoses and connections, and cleaning the radiator. 4. Fuel System Inspection: The fuel system of the generator should be inspected for leaks, blockages, and contamination. Clean fuel filters and fuel lines are crucial for ensuring optimal engine performance. 5. Battery Maintenance: The battery of the generator should be inspected, tested, and replaced as needed to ensure reliable starting and operation. Regular battery maintenance helps in preventing starting failures. Conclusion Performance analysis of diesel generators is essential for ensuring the reliability, efficiency, and longevity of the power generation system. By monitoring key performance parameters, conducting thorough testing, and implementing regular maintenance practices, operators can optimize the performance of diesel generators and prevent unexpected downtime. By investing in performance analysis and maintenance, businesses and individuals can rely on diesel generators as a dependable source of backup power in times of need.

Testing Methods Various testing methods can be used to analyze the performance of diesel generators effectively. These testing methods help in assessing the key performance parameters and identifying any deviations from the expected values. Some of the commonly used testing methods for diesel generators include: 1. Load Bank Testing: Load bank testing involves simulating real-world operating conditions by applying a load to the generator. This test helps in evaluating the performance of the generator under different load levels and assessing its capacity to handle varying loads. 2. Voltage and Frequency Testing: Voltage and frequency testing involves measuring the voltage and frequency output of the generator using specialized equipment. This test helps in ensuring that the generator is providing the correct voltage and frequency levels. 3. Fuel Consumption Analysis: Fuel consumption analysis involves monitoring the fuel consumption of the generator over a specific period. By analyzing fuel consumption patterns, operators can identify any anomalies and optimize fuel usage. 4. Thermal Imaging: Thermal imaging is used to detect temperature variations in the engine, alternator, and other components of the generator. This non-invasive method helps in identifying overheating issues and potential failures. Maintenance Practices In addition to performance analysis, regular maintenance practices are essential for ensuring the optimal performance and longevity of diesel generators. Proper maintenance helps in preventing breakdowns, reducing downtime, and extending the lifespan of the generator. 300KW Diesel Generator For Sale of the key maintenance practices for diesel generators include: 1. Regular Inspections: Conducting regular visual inspections of the generator for signs of wear, leaks, or damage is essential for detecting potential issues early on. 2. Oil and Filter Changes: Regular oil and filter changes are necessary to ensure the proper lubrication and cooling of the engine. Dirty oil and filters can lead to engine damage and reduced efficiency. 3. Cooling System Maintenance: The cooling system of the generator should be inspected and maintained regularly to prevent overheating. This includes checking coolant levels, inspecting hoses and connections, and cleaning the radiator. 4. Fuel System Inspection: The fuel system of the generator should be inspected for leaks, blockages, and contamination. Clean fuel filters and fuel lines are crucial for ensuring optimal engine performance. 5. Battery Maintenance: The battery of the generator should be inspected, tested, and replaced as needed to ensure reliable starting and operation. Regular battery maintenance helps in preventing starting failures. Conclusion Performance analysis of diesel generators is essential for ensuring the reliability, efficiency, and longevity of the power generation system. By monitoring key performance parameters, conducting thorough testing, and implementing regular maintenance practices, operators can optimize the performance of diesel generators and prevent unexpected downtime. By investing in performance analysis and maintenance, businesses and individuals can rely on diesel generators as a dependable source of backup power in times of need.